Tech Theory: Technical…Practical… Interesting Automation Industrial Solutions

At DELCO, we understand the importance of customer satisfaction and strive to meet the unique needs of every client. As a reliable valve supplier, we are committed to providing excellent customer service and high-quality products to ensure optimal performance and longevity. By choosing DELCO as your trusted control air supplier, you can benefit from customized valve assemblies designed specifically to meet your requirements, enhancing efficiency and reducing downtime.

Butterfly Valve: Principles, Types, and Uses

Butterfly valves are essential components in modern fluid control systems, known for their efficiency and versatility. With their simple yet effective design, butterfly valves regulate the flow of fluids through pipelines by using a rotating disc mechanism. They are highly valued across various industries for their cost-effectiveness, ease of installation, and reliable performance. In this article, we will explore the working principles of butterfly valves, the different types available, and their diverse industrial applications, providing a comprehensive overview of why they are a popular choice in fluid management.

Table of contents

What is a Butterfly Valve?

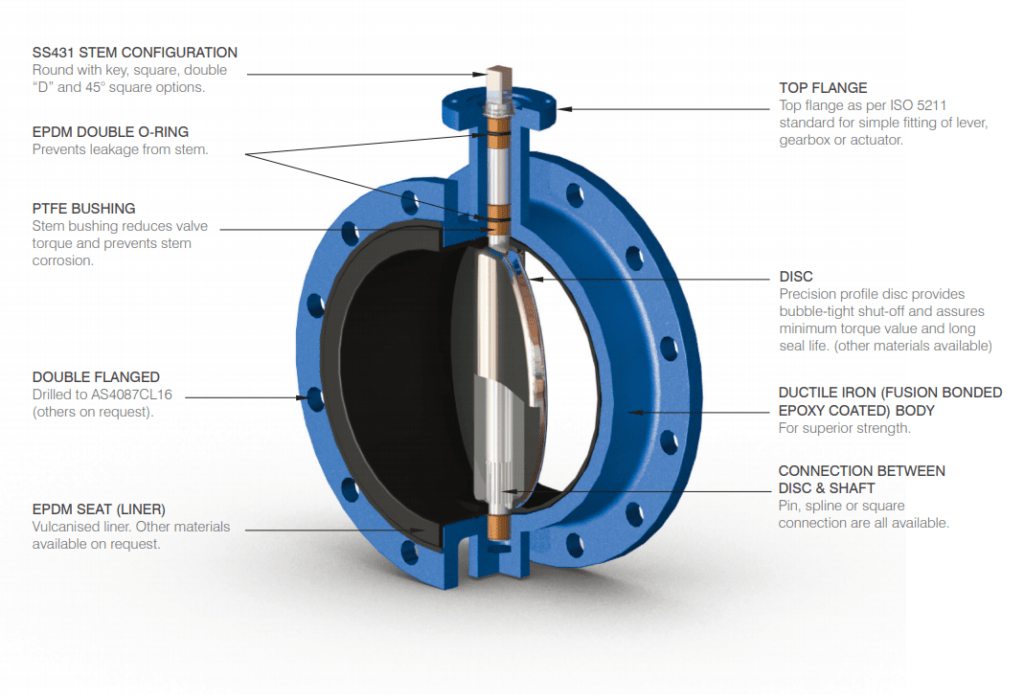

A butterfly valve is a crucial component in fluid control systems, widely utilized across various industries. This valve features a rotating disc (known as the valve plate) that regulates or isolates the flow of fluids. Butterfly valves are favored for their cost-effectiveness, lightweight design, and ease of installation. Their versatile nature makes them a popular choice in numerous industrial applications.

How Does a Butterfly Valve Work?

The working principle of a butterfly valve revolves around its rotating disc. When the actuator turns, the valve plate rotates within the pipeline, typically by a quarter turn (90 degrees), allowing the valve to either fully open or close. The valve plate creates a tight seal against the valve seat when closed, blocking fluid flow completely. Even when fully open, the valve plate remains in the flow path, which can lead to some pressure drop.

Types of Butterfly Valves

1. Wafer Butterfly Valve

The wafer butterfly valve is designed to ensure bi-directional pressure sealing to prevent backflow. It uses precision-sealed gaskets and flat valve faces on both upstream and downstream sides. Although this type of valve offers limited flow control range and may be prone to clogging, it provides strong chemical resistance and versatility.

2. Lug Butterfly Valve

Lug butterfly valves feature threaded inserts on both sides of the valve body, allowing installation between two flanges with bolts, without needing nuts. They are often used in lower pressure applications, such as dead-end services. Lug valves are highly resistant to chemicals and high temperatures, making them suitable for a variety of environmental conditions.

3. Rotary Valve

The rotary valve is a specialized butterfly valve designed for powder processing industries. Unlike traditional flat butterfly valves, it has a pocket-like structure. When closed, it provides effective sealing, and during rotation, it allows solid materials to pass through. This type of valve is ideal for bulk material handling and is usually smaller than 300 mm, often operated pneumatically with 180-degree rotation.

Industrial Applications of Butterfly Valves

Butterfly valves play a significant role in multiple industries, including:

Pharmaceutical Industry: Butterfly valves control fluid flow in pharmaceutical manufacturing processes. Their efficient flow regulation and easy maintenance make them a preferred choice.

Chemical Industry: In chemical processes, butterfly valves effectively manage the flow of various chemicals, accommodating a broad range of pressures and chemical conditions.

Food Industry: Butterfly valves are used in food processing and conveying systems to control fluid flow. Their ease of cleaning and maintenance aligns with food safety requirements.

Oil and Gas Industry: Due to their cost-effectiveness and ease of installation, butterfly valves are increasingly replacing ball valves in the oil and gas sector. While they cannot perform “pigging” for pipeline cleaning, their fluid control capabilities are significant.

Summary

Butterfly valves are a vital element in fluid control systems, celebrated for their efficiency and simplicity. They operate using a rotating disc to manage the flow of fluids, offering a cost-effective and lightweight solution suitable for various industrial applications. The main types of butterfly valves—wafer, lug, and rotary—each serve different purposes and conditions, from handling chemicals to processing powders. Their versatility and ease of maintenance make them a preferred choice across industries such as pharmaceuticals, chemicals, food processing, and oil and gas. Understanding the principles, types, and applications of butterfly valves highlights their significant role in effective fluid management.

Why more and more international valve brands choose DELCO for OEM service?

Founded in 2011, DELCO is a global leader in the industrial sector. Our main products include electric actuator valves, pneumatic actuator valves, automation actuators and solenoid valves. For nearly 20 years, we have utilized our products, engineering expertise and industrial automation solutions to solve countless industrial project problems for our customers, including food, beverage, chemical, water treatment, pharmaceutical, natural gas, oil and HVAC projects. We currently have five subsidiaries and more than 50 distributors around the world providing rapid response service.

All DELCO products undergo a 100% in-house design, engineering and manufacturing process led by highly skilled and experienced engineers using Italian and German technology to manufacture high quality, safe, reliable and value for money valves, actuators and solutions. Manufacturing standards can be demonstrated by the certifications obtained over the years.

And with the ISO 9001:2015 Quality Management System certification as well as many other certifications such as: SGS, RoHS, CNEX, TUV, CE, FDA. these certifications prove that DELCO adheres to the highest quality and safety standards worldwide when manufacturing its products.

How to get a quick quote for industrial valves?

If you have questions about valves or want to get a quote, please feel free to contact us, we will reply within 6 hours. Phone +86 159 8960 2972, WhatsApp +86 159 8960 2972 or email marketing [email protected].

DELCO’s quality, competitive prices and excellent service make it the best valve partner to help you grow your business. Customize your valves, we have no minimum order.

At DELCO, we understand the importance of customer satisfaction and strive to meet the unique needs of every client. As a reliable control valve supplier, we are committed to providing excellent customer service and high-quality products to ensure optimal performance and longevity. By choosing DELCO as your trusted control valve supplier, you can benefit from customized valve assemblies designed specifically to meet your requirements, enhancing efficiency and reducing downtime.

Furthermore, our competitive pricing on electronic pressure regulators enables you to offer top-notch solutions. As one of the leading control valve manufacturers, we take pride in delivering reliable valves that not only meet industry standards but also contribute to the overall profitability of your business. By partnering with DELCO, you can have peace of mind knowing that you are making a wise choice for the long-term success of your company.