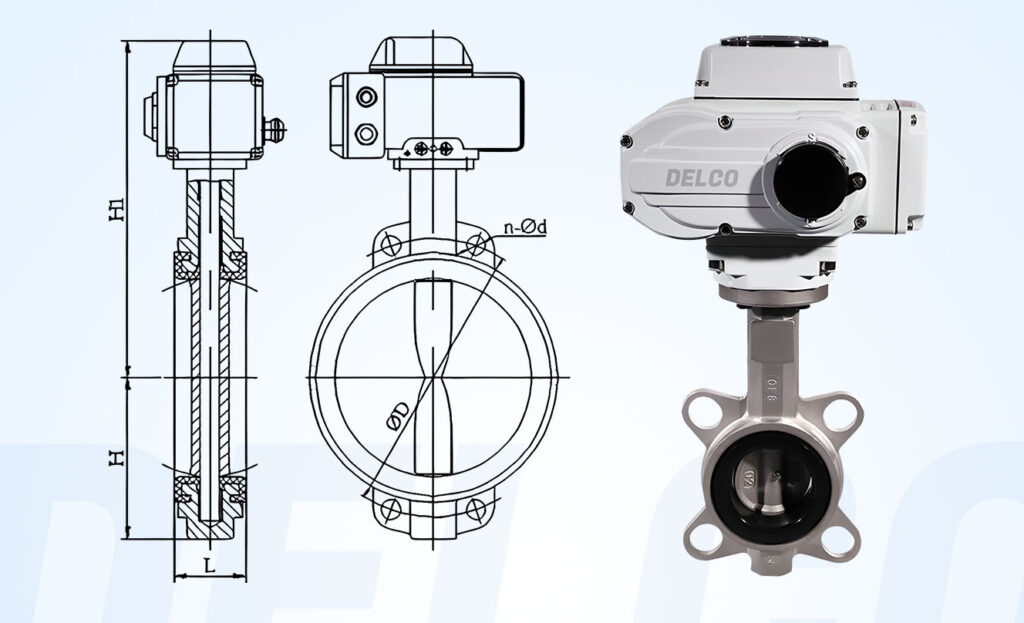

Electric Stainless Steel Wafer Butterfly Valve-DK56-WB-S

Electric stainless steel wafer butterfly valve are integral components in modern industrial processes, providing precise fluid control solutions that optimize performance, enhance productivity, and ensure operational safety. Their ability to offer precise control, reliable operation, and remote control capability makes them indispensable in fluid handling systems across various industries.

In conclusion, electric stainless steel wafer butterfly valves represent a cornerstone of fluid control technology, offering unmatched precision, reliability, and versatility in industrial applications. Their innovative design, electric actuation, and numerous advantages make them indispensable components in fluid handling systems, ensuring optimal performance and efficiency in diverse industrial processes.

Model: Electric Butterfly Valve

Size Range: 2” to 16”

Pressure Range: 1.0MPa~1.6MPa

Material: Stainless Steel 304/316, Cast Iron

Description

Electric stainless steel wafer butterfly valves are engineered with robust stainless steel bodies, which provide exceptional resistance to corrosion, abrasion, and harsh operating conditions. The valve’s unique butterfly disc, mounted on a central shaft, controls the flow of fluid within the pipeline. The electric actuator, typically mounted atop the valve, drives the disc’s rotation, allowing for precise modulation of flow rates.

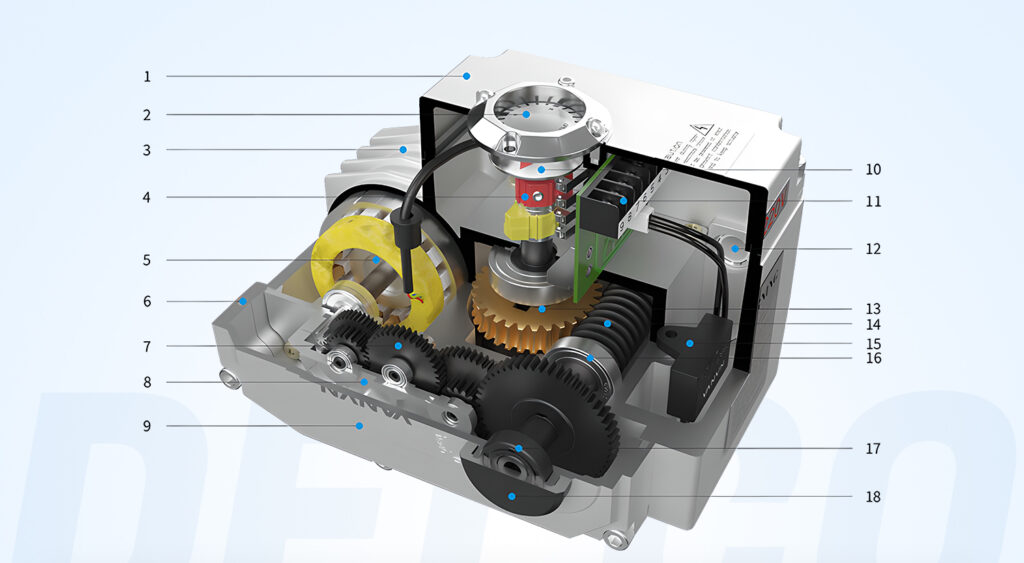

The electric actuator is the central component of the electric stainless steel wafer butterfly valve, providing the power and control necessary to open and close the valve. Powered by electricity, the actuator receives signals from control systems such as programmable logic controllers (PLCs) or distributed control systems (DCS), enabling precise positioning and remote operation. Electric actuation offers numerous advantages, including rapid response times, accurate control, and compatibility with automated processes.

Stainless Steel wafer Butterfly Valve technical Parameter

| Valve Body | Nominal size | Body Material | End Connection | Operating Pressure | Structure |

| DN50-DN400 | Stainless steel | Wafer | 1.0 / 1.6 MPa (10 / 16 bar) |

Midline structure/A-Type | |

| Valve components | Sealing material | Disc Material | Stem Material | Applicable media | Design standard |

| PTFE,NBR,EPDM | SS304 | Stainless Steel | Water, Air, Gas, Oil, Liquid | ISO, DIN, IDF, SMS, 3A | |

| ON/OFF Type | Regulation Type | Field operation | Voltage Optional | Protection Class | Torque Range |

| Feedback: the active contact signal, passive contact signal, resistance, 4-20mA | Input & Output signal: DC 4-20mA, DC 0-10V, DC 1-5V | The Field, Remote Control Switch Regulation and MODBUS, PROFIBUS Field Bus | AC110-240V 380V 50/60HZ: DC12V, DC24V, Special Voltage Can be Customized | IP65, Explosion Proof Construction Are Available: EX ll BT4 | 50Nm to 2500Nm |

Stainless Steel wafer Butterfly Valve Advantages:

Precise Control: Electric stainless steel wafer butterfly valves offer precise control over fluid flow rates, enabling accurate modulation and regulation of process parameters.

Reliable Operation: With electric actuation, these valves provide consistent and repeatable performance, reducing the risk of manual errors and ensuring reliable operation over extended periods.

Remote Control Capability: Electric stainless steel wafer butterfly valves can be remotely operated and integrated into automated control systems, allowing for seamless integration into modern industrial processes.

Durability: Constructed from stainless steel, these valves exhibit exceptional durability and resistance to corrosion, ensuring long-term reliability and minimal maintenance requirements.

Stainless Steel Butterfly Valve Applications:

Electric stainless steel wafer butterfly valves find applications in a wide range of industries and processes where precise fluid control is essential. Some common applications include:

Water Treatment: These valves are used in water treatment plants to regulate the flow of water, chemicals, and sludges, facilitating effective purification and distribution processes.

Chemical Processing: In chemical manufacturing plants, electric stainless steel butterfly valves control the flow of corrosive chemicals, solvents, and abrasive slurries, ensuring safe and efficient production processes.

Food and Beverage: Used in food processing facilities, these valves regulate the flow of ingredients, liquids, and cleaning solutions, meeting strict hygiene standards and ensuring product quality.

HVAC Systems: Electric stainless steel wafer butterfly valves play a crucial role in heating, ventilation, and air conditioning (HVAC) systems, regulating the flow of water or air to maintain optimal temperature and comfort levels in buildings.

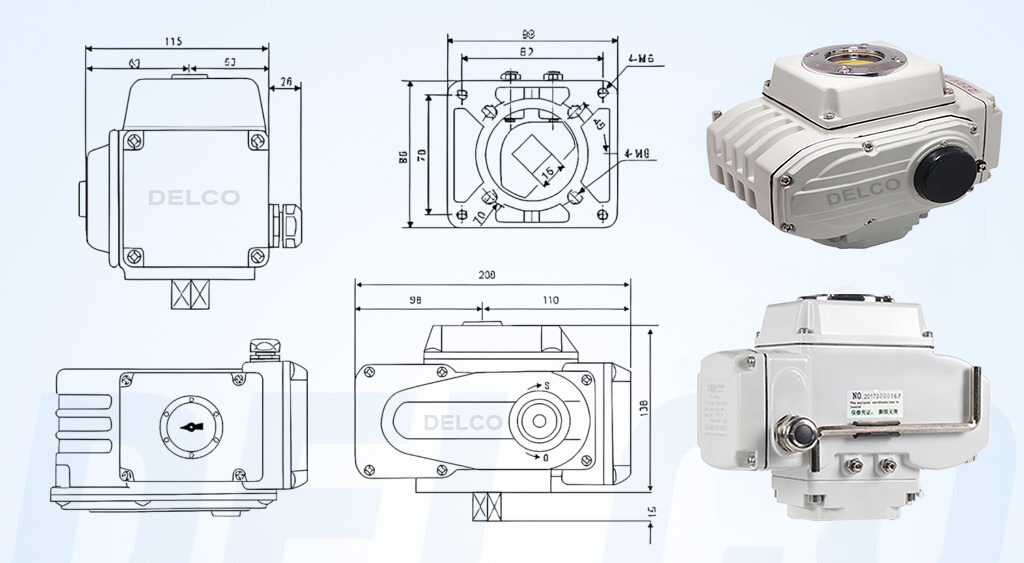

Electric Actuator:

ON/OFF Type Electric Actuator: Featuring a 90-degree rotation, this actuator offers AC/DC power supply, signal control, and manual override capabilities. With high torque of up to 4000Nm, it ensures reliable performance in demanding environments.

Modulating Type Electric Actuator: Adjust the open/close angle smoothly from 0 to 90 degrees with this actuator. Equipped with AC/DC power supply, signal control, and manual override, it delivers precise control and high torque of up to 4000Nm.

Intelligent Type Electric Actuator: Take control with ease using the intelligent actuator, allowing you to adjust the open/close angle with precision. Featuring an LED display screen for convenient monitoring, it offers AC/DC power supply, signal control, manual override, and high torque of up to 4000Nm.”

| Product Model: | DK56-WB-S | Housing Material: | Aluminum alloy |

| Waterproof Level: | IP67 | Motor power supply: | 24/110/220/380V AC±10%,24/110/220VDC 50/60HZ±10% |

| Motor: | Squirrel cage asynchronous motor | Itinerary: | 90°-270±10° (above 90° in advance) |

| Fail-safe: | Built-in thermal protection on: 120°C±5°C | Operating Temperature: | 97℃±15℃ |

| Indicator: | Continuous position indication | Manual operation: | Mechanical handles |

| Self-locking device: | The turbine and worm mechanism provide self-locking | Mechanical Limit: | 2 external adjustments |

| Terminal Holes: | M18 | Ambient Temperature: | -20℃-70℃ |

| Lubrication: | Aluminum-based grease EP type | Material: | Steel, aluminium alloy, aluminium bronze, polycarbonate |

| Ambient Humidity: | Up to 90% | Ingress Protection: | IP65; IP67; IP68 |

| Explosion-proof grade: | Exd II BT4; Exd II CT6 | Ambient Temperature: | -25℃-55℃ |

| Ambient Humidity: | 10~90%RH | Seismic Performance: | X Y Z 10 grams, 0.2-34HZ 30 minutes |

| Coating: | Dry powder, epoxy polyester | Manufacturing Standards: | GB/JB/HG/HG/ANSI/API/JIS/DIN/OTHER STANDARDS CUSTOMIZED |

One-time business is not our goal, we pursuit for long-term partner relationships.

We are not just providing simple quotes but experts in selection, calculation, and drawing.

ASK FOR A QUOTE

Related products

Offering Industry-Oriented Valve Solution For You

The company not only controls the quality in real time, but also zero tolerance for problems is the pursuit of high quality. Workers must undergo rigorous training and strict assessment before they can take up their jobs.

Quality Assurance

Calculation & Selection, Quality Control, Inspection, After-Sales Service, etc. Each Production Loop to Ensure Our Customers Have No Worries.

Services

At DELCO, we believe there always has a better valve solution for every single customer. We’re obsessively passionate about it, and our mission is to manufactures & supply a range of innovative control valves & pressure regulators backed by global service support, thereby guaranteeing zero defects within the shortest lead time.

Production Market

DELCO Has A Wide Reach, Exporting To Over 46 Nations. So We Have A Complete Picture Of The Market. Welcome To Become A Long-Term Business Partner With Us. Reliable Control Valves and Self-Operated Pressure RegulatorsManufacturer

Company Honor

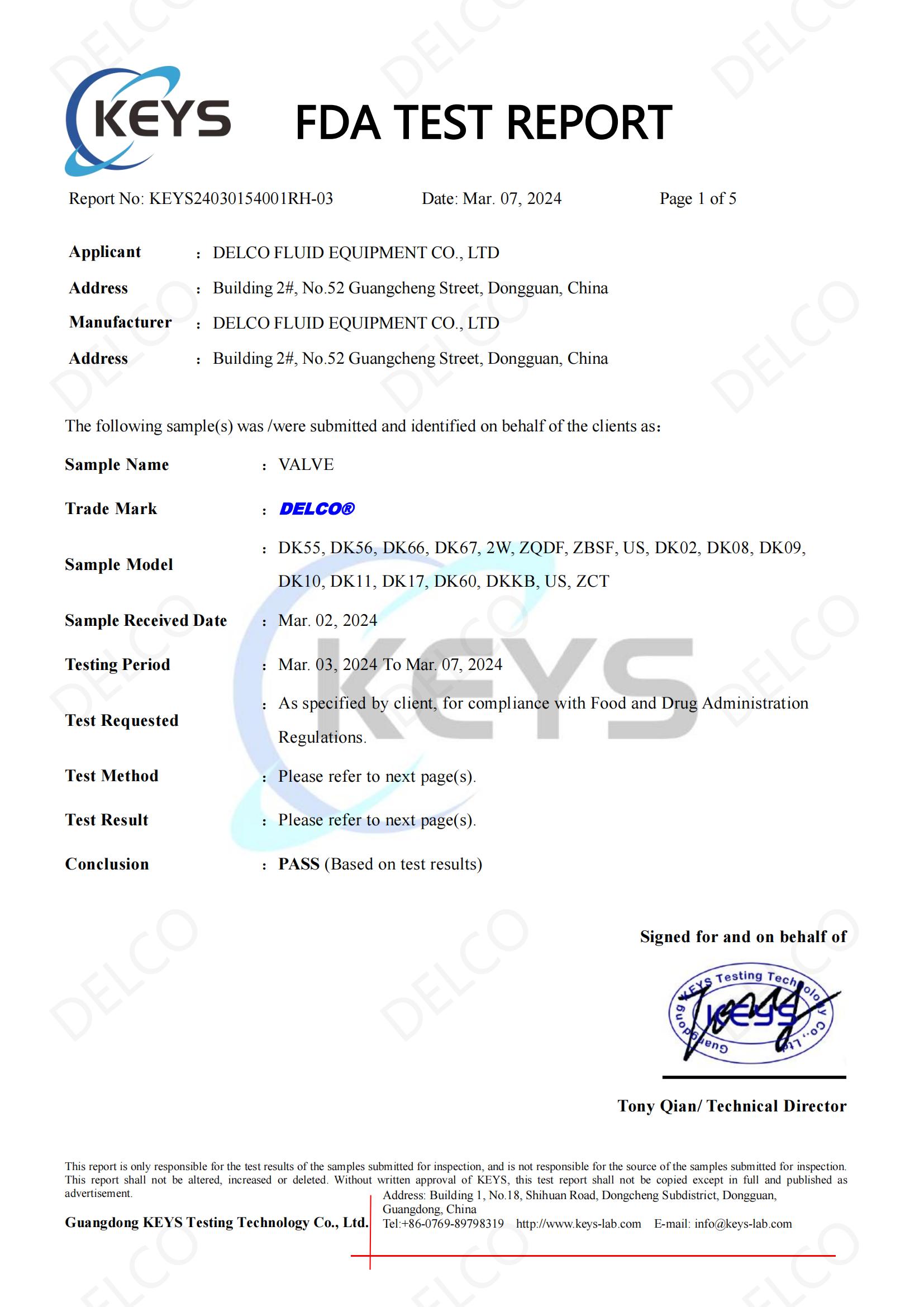

DELCO valve has CE, RoHS, FDA, Explosion-proof electrical apparatus.

For over 20 years, DELCO Valves has been committed to providing our customers with high quality valves.

DELCO has always been centered around one thing: 100% customer satisfaction. We strive for continuous improvement in all aspects of our daily operations. Our mission, coupled with a product line that is manufactured to the highest quality standards, continues to be what sets us apart from our competition. At Powell, all of our facilities are ISO 9001 “Global Quality” certified.

As a leading manufacturer of industrial valves, we offer a wide range of products. Our product lines include: gate valves, check valves, globe valves, check valves, double plate check valves and high performance butterfly valves. With the most complete multi-turn product line from a single-source manufacturer, our valves are manufactured to the highest quality standards using ultra-modern manufacturing techniques and astute material sourcing.

As a full-service valve company, we offer a wide range of products as well as retrofit and field services. Our valve expertise is unrivaled and we look forward to meeting your future valve needs!