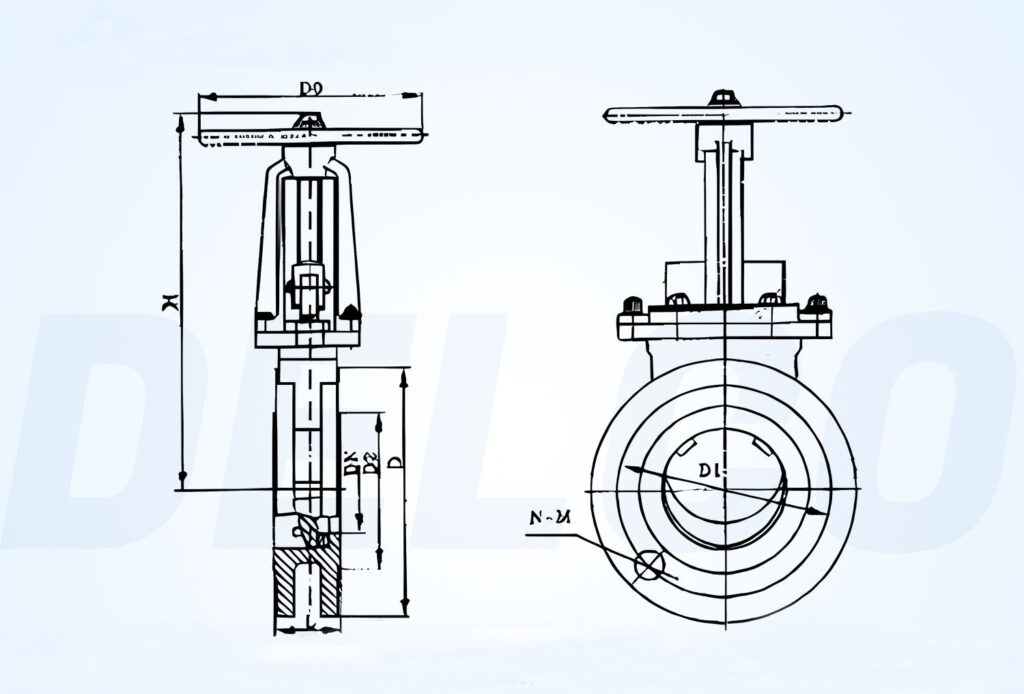

DELCO Manual Flange Knife Gate Valve

A manual blade gate valve is a type of valve that uses a gate or wedge-shaped disc to control fluid flow through a pipeline. The gate is manually operated by turning a lever or wheel, which raises or lowers the gate to open or close the valve. The gate has a sharp edge, hence the so-called “knife gate” that allows it to cut through solids that may be present in the liquid. This type of valve is commonly used in applications where quick shut-off is required, such as irrigation systems, wastewater treatment plants, and industrial process lines. It is also often used in applications where solids are expected to be present in the liquid, as the sharp edge of the door allows it to effectively cut off and close the flow of solids.

Model: Manual Valve

Size Range: 2″ to 24″ ( Special size can be customized )

Pressure Range: 1.6MPa to 6.4MPa

Material: Cast Iron, Cast Steel, Ductile Iron, Stainless Steel

Description

Manual knife gate valves play a crucial role in industrial flow control, offering a reliable, cost-effective, and versatile solution for managing the flow of fluids, slurries, and solids. Their simple design, robust construction, and excellent sealing capabilities make them suitable for a wide range of applications, ensuring efficient operation and minimal maintenance. Whether used in wastewater treatment, mining, chemical processing, or agriculture, manual knife gate valves are an essential tool for industries requiring effective flow control solutions.

Manual knife gate valves are an essential component in various industrial processes, offering a practical solution for controlling the flow of fluids, slurries, and bulk materials. Characterized by their simplicity, durability, and effectiveness, these valves have become indispensable in sectors such as wastewater treatment, mining, chemical processing, and agriculture. This introduction aims to provide an overview of manual knife gate valves, including their design, operation, applications, and benefits.

Technical Parameters

| Size | DN50~DN600 (2”~24”) | Pressure Range | 1.6~6.4Mpa |

| Temperature | -38℃~1100℃ | Sealing Material | PTFE Metal Seal |

| End connection | Flange | Flange Drilling | ANSI/ GB/ DIN/ GIS/ NF/ BS |

| Main Materials | Cast Iron | Actuation | Manual, Motorized,or Pneumatic |

Manual knife gate valve

Design and Operation:

The manual knife gate valve features a straightforward design, consisting of a gate made of a flat metal plate, which slides in and out of the path of the fluid, providing a seal to control flow. This gate is actuated manually, typically through a handwheel or a lever, allowing the operator to adjust the position of the gate and, consequently, the flow rate of the material passing through the valve. The simplicity of the design ensures easy operation and maintenance, making it a cost-effective solution for flow control.

Knife gate valves are designed to cut through slurry and other viscous fluids, making them particularly useful in applications involving tough fluids that might clog other types of valves. The sharp edge of the gate can slice through solids and sediments, providing a clear path for the fluid to flow without significant obstruction.

Applications:

Manual knife gate valves are widely used in industries where the flow of viscous fluids, slurries, or solid materials needs to be controlled. In the wastewater treatment industry, they are used to manage the flow of sewage and sludge, offering reliable performance even in the presence of solid waste and debris. In mining and mineral processing, knife gate valves control the flow of abrasive slurries, ensuring efficient operation despite the challenging conditions. The chemical industry benefits from their ability to handle corrosive fluids, while the agricultural sector uses them for irrigation systems and the management of animal waste.

Benefits:

One of the key advantages of manual knife gate valves is their cost-effectiveness. The simplicity of their design not only makes them affordable but also minimizes maintenance requirements, reducing the overall cost of ownership. Additionally, their ability to cut through solids and viscous fluids reduces the likelihood of clogs and blockages, ensuring smoother operation and less downtime for cleaning and repairs.

Another significant benefit is the versatility of manual knife gate valves. They can handle a wide range of fluids and materials, from water and wastewater to chemicals and slurries. This versatility, combined with their robust construction, makes them suitable for use in harsh environments and challenging industrial applications.

Furthermore, manual knife gate valves offer excellent sealing capabilities. When the gate is fully closed, it provides a tight seal that prevents leaks, enhancing the efficiency and safety of industrial processes.

One-time business is not our goal, we pursuit for long-term partner relationships.

We are not just providing simple quotes but experts in selection, calculation, and drawing.

ASK FOR A QUOTE

Related products

Offering Industry-Oriented Valve Solution For You

The company not only controls the quality in real time, but also zero tolerance for problems is the pursuit of high quality. Workers must undergo rigorous training and strict assessment before they can take up their jobs.

Quality Assurance

Calculation & Selection, Quality Control, Inspection, After-Sales Service, etc. Each Production Loop to Ensure Our Customers Have No Worries.

Services

At DELCO, we believe there always has a better valve solution for every single customer. We’re obsessively passionate about it, and our mission is to manufactures & supply a range of innovative control valves & pressure regulators backed by global service support, thereby guaranteeing zero defects within the shortest lead time.

Production Market

DELCO Has A Wide Reach, Exporting To Over 46 Nations. So We Have A Complete Picture Of The Market. Welcome To Become A Long-Term Business Partner With Us. Reliable Control Valves and Self-Operated Pressure RegulatorsManufacturer

Company Honor

DELCO valve has CE, RoHS, FDA, Explosion-proof electrical apparatus.

For over 20 years, DELCO Valves has been committed to providing our customers with high quality valves.

DELCO has always been centered around one thing: 100% customer satisfaction. We strive for continuous improvement in all aspects of our daily operations. Our mission, coupled with a product line that is manufactured to the highest quality standards, continues to be what sets us apart from our competition. At Powell, all of our facilities are ISO 9001 “Global Quality” certified.

As a leading manufacturer of industrial valves, we offer a wide range of products. Our product lines include: gate valves, check valves, globe valves, check valves, double plate check valves and high performance butterfly valves. With the most complete multi-turn product line from a single-source manufacturer, our valves are manufactured to the highest quality standards using ultra-modern manufacturing techniques and astute material sourcing.

As a full-service valve company, we offer a wide range of products as well as retrofit and field services. Our valve expertise is unrivaled and we look forward to meeting your future valve needs!