Self-Operated Nitrogen Sealing Control Valve-ZZYVP-16

ZZYVP type commander operates the self-operated pressure regulating valve (nitrogen sealing valve), which is an energy-saving pressure regulating valve that can automatically adjust and stabilize the pressure behind the valve to a set value by using the pressure change of the regulated medium itself without external energy. The pressure setting of the valve is realized on the commander, which is convenient and fast, and the pressure setting value can be adjusted at will during operation; The control precision is high, which is twice as high as that of ordinary directly operated self-operated pressure regulating valve, and is suitable for occasions with high control precision requirements. It is widely used in chemical, petroleum, metallurgy, electric power, textile and other industrial sectors as automatic regulation of production process.

Model: Self-Operated Nitrogen Sealing Control Valve

Size Range: 1/2”~12′

Pressure Range:1.6~6.4

Material: WCB, Stainless Steel 304/306

Description

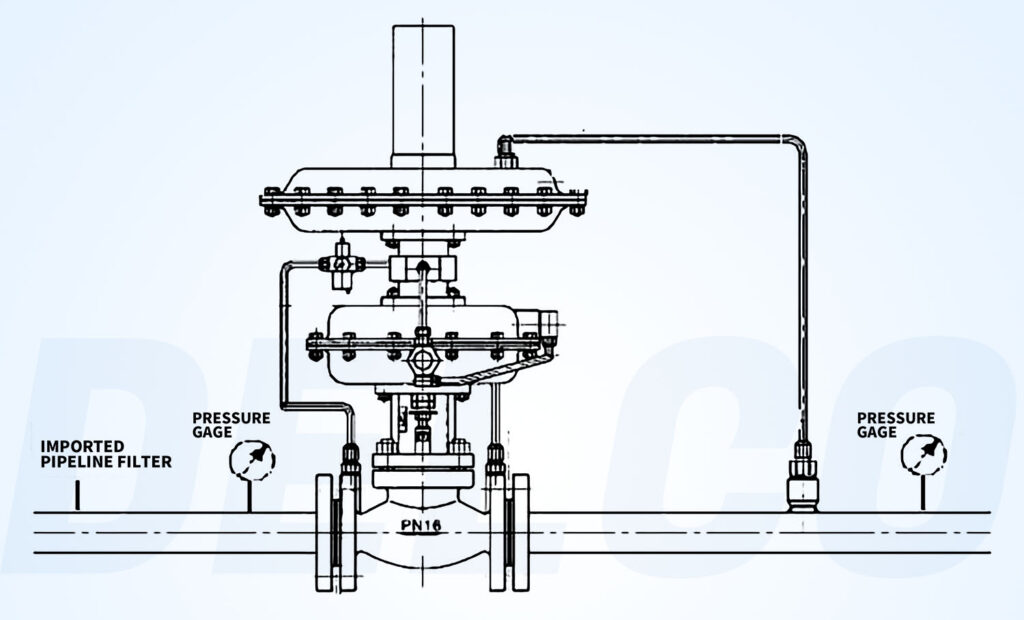

Self operated nitrogen sealing valve is mainly used for constant control of nitrogen pressure at the top of the storage tank to protect the materials inside the tank from being nitrided and ensure the safetyof the storage tank, the pressure regulating valve with a controller consists of two main parts: A quick release valve and a self operated micro pressure regulating valve. The quick release valve consists of a pressure controller and a single seat shut-off valve.

Working principle: When the pressure inside the storage tank rises to the set pressure the ouick release valve ouickly opens to release excess pressure inside the tank. When the pressure inside the storage tank decreases, the micro pressure regulating yai veopens and fils the tank with nitrogen gas dueto the fact that the micro pressure regulating vaive must re used at a pressur ebelow o impa and the on-site pressure is high.A pressure regulating valve must be installed to reduce the pressure to below o impabeforeit can be used. The nominal pressure is 0.Impa,and the pressure can be set in stages,ranging from o.Skpa to below 66kpa.The mediumtem perature iss 80 ”c.

Technical Parameters

| DN(mm) | Seat Diameter (mm) | Rated flow coefficient Kv | Pressure regulation range KPa | Nominal pressure PN (MPa). | Temperature of the medium to be adjusted (°C) | Flow characteristics | Adjustment Accuracy (%) | Effective area of actuator (cm2). | Pressure tube interface |

| 20 | 6 | 0.32 | 0.2~0.5、 0.5~1.5、 1~3、 4.0~10 | 1.6、2.5 | -5~+75 | Hurry up | ≤±5 | 200 | M16×1.5 |

| 15 | 5 | ||||||||

| 20 | 8 | ||||||||

| 25 | 25 | 11 | |||||||

| 40 | 32 | 20 | |||||||

| 280 | |||||||||

| 40 | 30 | ||||||||

| 50 | 50 | 48 | |||||||

| 80 | 65 | 75 | 400 | ||||||

| 80 | 120 | ||||||||

| 100 | 100 | 190 | |||||||

| 150 | 125 | 300 | 600 | ||||||

| 150 | 480 |

Self-Operated Nitrogen Sealing Valve

Self-Operated Nitrogen Sealing Valves Applications:

The versatility and reliability of self-operated nitrogen sealing valves make them indispensable in a variety of industrial applications. Some common applications include:

Chemical Processing: In chemical manufacturing and processing plants, self-operated nitrogen sealing valves are used to create inert atmospheres in storage tanks, reactors, and other equipment, preventing oxidation, contamination, and hazardous reactions.

Food and Beverage Production: In the food and beverage industry, these valves are employed to maintain a nitrogen blanket over liquid products during storage and packaging, preventing spoilage, oxidation, and microbial growth.

Pharmaceutical Manufacturing: In pharmaceutical production facilities, self-operated nitrogen sealing valves are utilized to create sterile environments in processing equipment and storage vessels, ensuring product purity and stability.

Electronics Manufacturing: In semiconductor fabrication and electronics manufacturing, these valves play a critical role in preventing moisture and oxygen ingress during assembly and packaging processes, safeguarding sensitive electronic components and devices.

Self-Operated Nitrogen Sealing Valves Advantages:

Autonomous Operation: Self-operated nitrogen sealing valves require no external power sources or complex control systems, relying solely on the pressure of the nitrogen gas itself to regulate flow rates and maintain seal pressure, reducing reliance on external infrastructure and enhancing system reliability.

Efficiency: By automatically adjusting flow rates in response to changes in seal pressure, these valves help optimize nitrogen usage and reduce operating costs in sealing applications, improving efficiency and sustainability.

Reliability: With their robust design and self-regulating mechanism, self-operated nitrogen sealing valves offer reliable performance in a wide range of operating conditions, ensuring consistent seal pressure and system integrity.

Flexibility: Self-operated nitrogen sealing valves are highly adaptable and can be customized to meet the specific requirements of different applications, making them suitable for a variety of sealing tasks in different industries.

self-operated nitrogen sealing valve represents a significant advancement in sealing technology, offering autonomous and efficient control over seal pressure in industrial processes. With their unique self-regulating mechanism and reliability, these valves provide enhanced safety, integrity, and efficiency in sealing applications across various industries. As technology continues to evolve, self-operated nitrogen sealing valves will remain at the forefront of sealing innovation, driving efficiency, reliability, and performance in industrial processes worldwide.

One-time business is not our goal, we pursuit for long-term partner relationships.

We are not just providing simple quotes but experts in selection, calculation, and drawing.

ASK FOR A QUOTE

Related products

Offering Industry-Oriented Valve Solution For You

The company not only controls the quality in real time, but also zero tolerance for problems is the pursuit of high quality. Workers must undergo rigorous training and strict assessment before they can take up their jobs.

Quality Assurance

Calculation & Selection, Quality Control, Inspection, After-Sales Service, etc. Each Production Loop to Ensure Our Customers Have No Worries.

Services

At DELCO, we believe there always has a better valve solution for every single customer. We’re obsessively passionate about it, and our mission is to manufactures & supply a range of innovative control valves & pressure regulators backed by global service support, thereby guaranteeing zero defects within the shortest lead time.

Production Market

DELCO Has A Wide Reach, Exporting To Over 46 Nations. So We Have A Complete Picture Of The Market. Welcome To Become A Long-Term Business Partner With Us. Reliable Control Valves and Self-Operated Pressure RegulatorsManufacturer

Company Honor

DELCO valve has CE, RoHS, FDA, Explosion-proof electrical apparatus.

For over 20 years, DELCO Valves has been committed to providing our customers with high quality valves.

DELCO has always been centered around one thing: 100% customer satisfaction. We strive for continuous improvement in all aspects of our daily operations. Our mission, coupled with a product line that is manufactured to the highest quality standards, continues to be what sets us apart from our competition. At Powell, all of our facilities are ISO 9001 “Global Quality” certified.

As a leading manufacturer of industrial valves, we offer a wide range of products. Our product lines include: gate valves, check valves, globe valves, check valves, double plate check valves and high performance butterfly valves. With the most complete multi-turn product line from a single-source manufacturer, our valves are manufactured to the highest quality standards using ultra-modern manufacturing techniques and astute material sourcing.

As a full-service valve company, we offer a wide range of products as well as retrofit and field services. Our valve expertise is unrivaled and we look forward to meeting your future valve needs!