DELCO Valve Multi-Turn Motorized Gate Valve Actuator

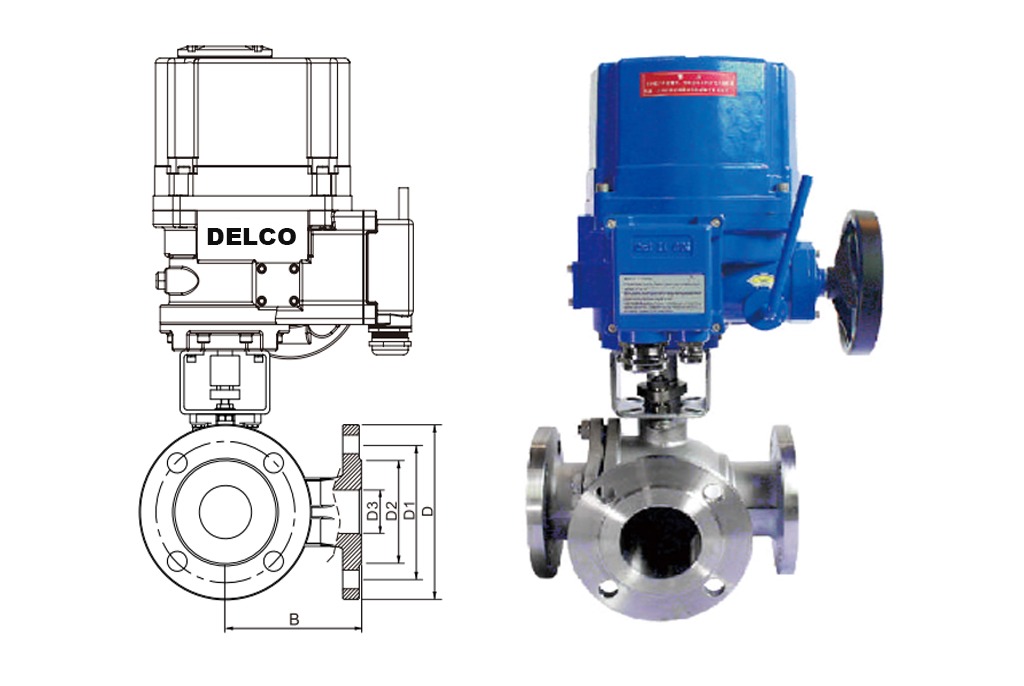

Introducing our Multi-Turn Motorized Gate Valve Actuator, featuring a robust aluminum alloy body construction. This actuator offers adjustable rotation from 0 to 90 degrees, with manual override functionality for added convenience. With a torque range of 50Nm to 5000Nm, it’s suitable for various valve sizes and applications.

Operating at 380V nominal voltage, with motor power options from 0.12KW to 15KW, our actuator ensures reliable performance in temperatures ranging from -40°C to 80°C. Compatible with valve stems from 28mm to 80mm, it’s ideal for gate valves, knife-gate valves, globe valves, diaphragm valves, and penstocks. Trust our Multi-Turn Motorized Gate Valve Actuator for precise and efficient valve control.

Model: Multi-Turn Motorized Gate Valve Actuator

Size Range: Z05 to Z1000

Output Torque: 50-10000N.m

Material: Aluminum Alloy

DELO Valve Multi-Turn Motorized Gate Valve Actuator Features

- Multi-turn Electric Actuator Torque Range: 50N.m – 10000N.m

- Rugged Type 4X weatherproof aluminum alloy enclosure

- Ambient temperature: -20℃~60℃(special order -60℃~80℃)

- Heavy-duty motor with overload protection

- Relative humidity: 95%(when25℃)

- Power supply: general: single-phase 220V, 3 phase 380V(50Hz), long-distance DC24V; Single phase: 110V, 3 phase 415V, 660V(50Hz, 50Hz)

- Working time: 10 minutes for short time(special order can reach 15-60 minutes)

Multi-turn Actuator Main Techincal Specifications:

| Input Signal | 4mA~20mA, Passive contact |

| Power Supply | Conventional: three-phase, AC380V(50Hz) Special: Three Phase: AC660V, AC440V, AC415V(50Hz, 60Hz) Simplex: AC220V, AC110V(50Hz, 60Hz) Direct: DC12V, DC24V, DC48V |

| Basic error limit | ≤1% |

| Protection class | IP65, IP68. . |

| Explosion-proof grade | ExdllBT4, Exdll CT4 |

| Ambient temperature | ≤95%(25℃) |

| Environmental humidity | -30°C~+70°C(Optional: -40*C~+100*C) |

| Motor working system | Standard long-term, F-class insulation |

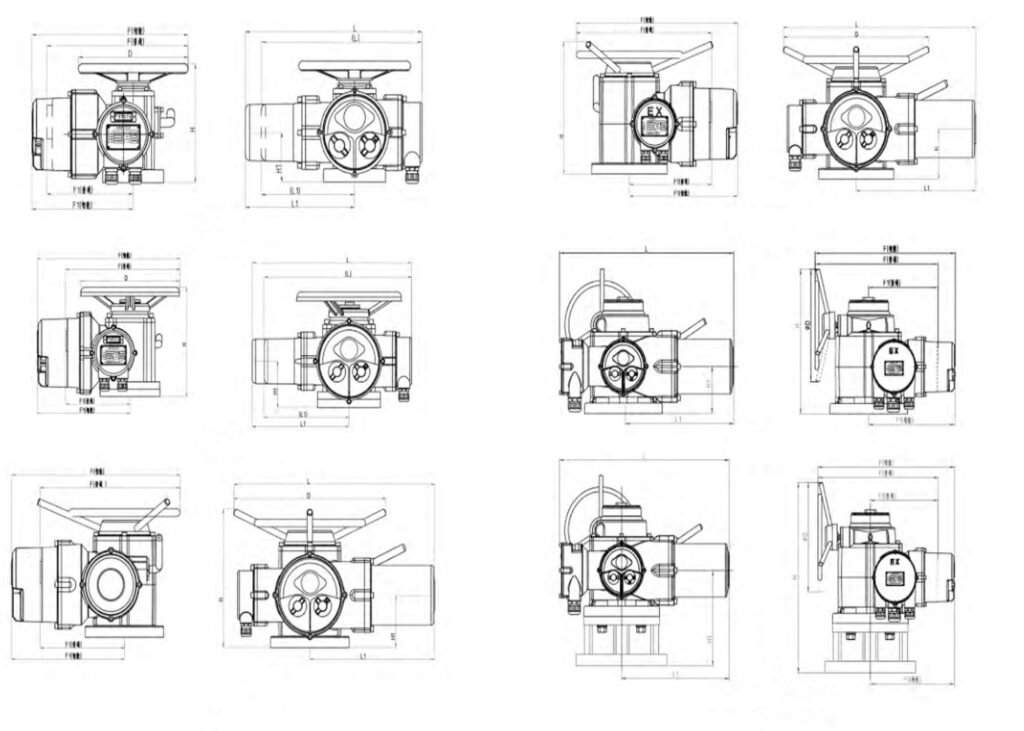

Types of Multi-turn Electric Actuator:

DELCO Valve provides four main types of multi-turn actuators: regulation, on-off, ordinary, and explosion-proof. These versatile actuators are waterproof and feature manual override settings. They find extensive use across various industries, including power plants, oil & gas fields, water treatment plants, chemicals, pharmaceuticals, and marine ships.

What Is Multi-turn Electric Actuator?

Comprising components such as an electric motor, gearbox, limit switches, and control circuitry, multi-turn electric actuators offer efficient and reliable operation. The electric motor converts electrical energy into mechanical force, which is then transmitted through the gearbox to generate the necessary torque for valve operation. Limit switches ensure accurate control over the actuator’s movement, guaranteeing precise positioning of the valve. These actuators play a crucial role in industrial automation, enhancing operational efficiency, and safety by enabling remote and automated valve control while minimizing the risk of human error.

A multi-turn electric actuator is an advanced electromechanical device used in industrial settings to precisely control linear motion, particularly for valves that require multiple rotations to fully open or close. Unlike quarter-turn actuators that rotate valves by 90 degrees, multi-turn actuators are designed to execute numerous rotations along the valve stem, enabling precise positioning of linear movement valves such as gate valves, globe valves, and rising stem ball valves.

Suitable for gate valve, globe valve, ball valve, and butterfly valve:

One-time business is not our goal, we pursuit for long-term partner relationships.

We are not just providing simple quotes but experts in selection, calculation, and drawing.

ASK FOR A QUOTE

Related products

Offering Industry-Oriented Valve Solution For You

The company not only controls the quality in real time, but also zero tolerance for problems is the pursuit of high quality. Workers must undergo rigorous training and strict assessment before they can take up their jobs.

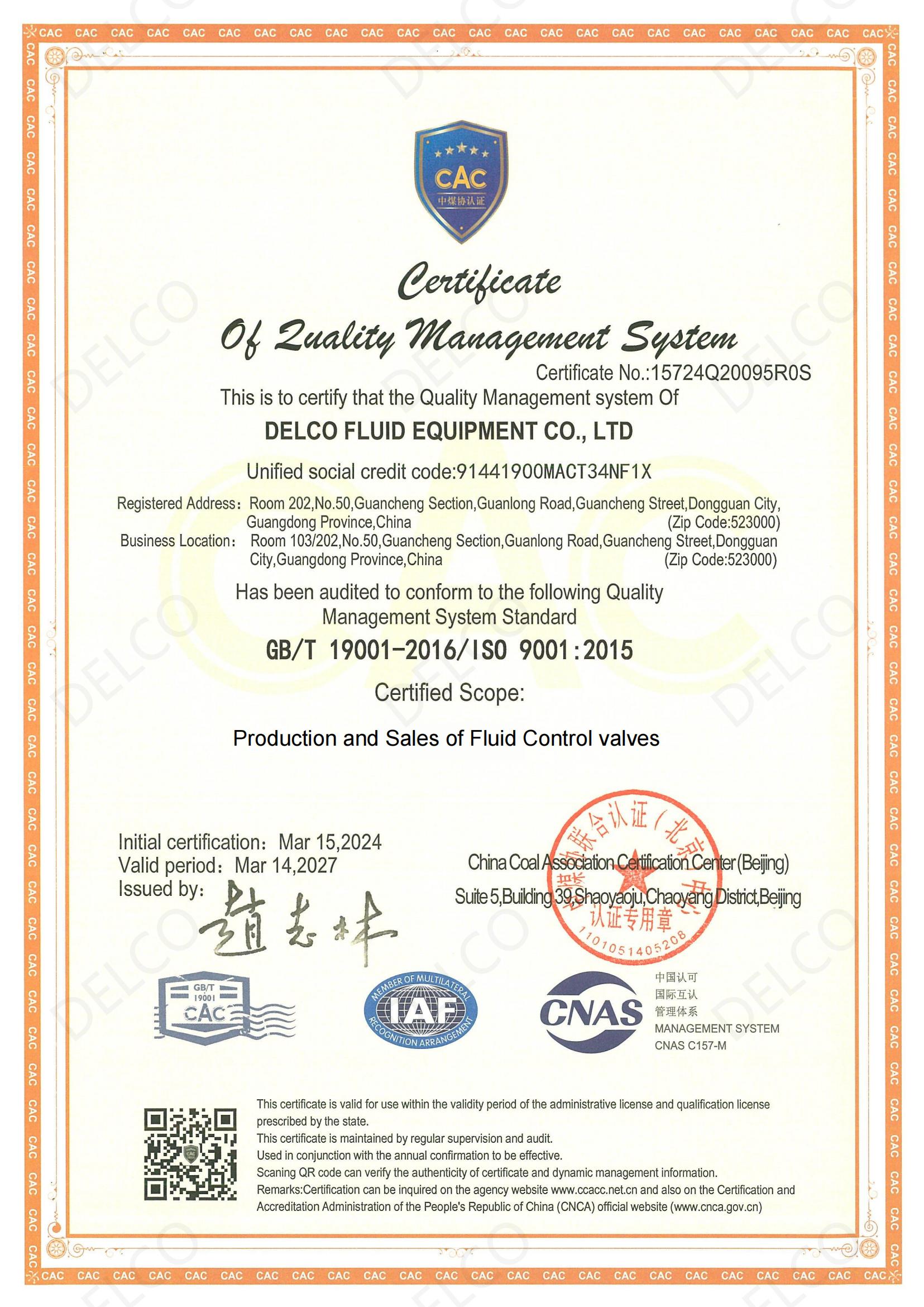

Quality Assurance

Calculation & Selection, Quality Control, Inspection, After-Sales Service, etc. Each Production Loop to Ensure Our Customers Have No Worries.

Services

At DELCO, we believe there always has a better valve solution for every single customer. We’re obsessively passionate about it, and our mission is to manufactures & supply a range of innovative control valves & pressure regulators backed by global service support, thereby guaranteeing zero defects within the shortest lead time.

Production Market

DELCO Has A Wide Reach, Exporting To Over 46 Nations. So We Have A Complete Picture Of The Market. Welcome To Become A Long-Term Business Partner With Us. Reliable Control Valves and Self-Operated Pressure RegulatorsManufacturer

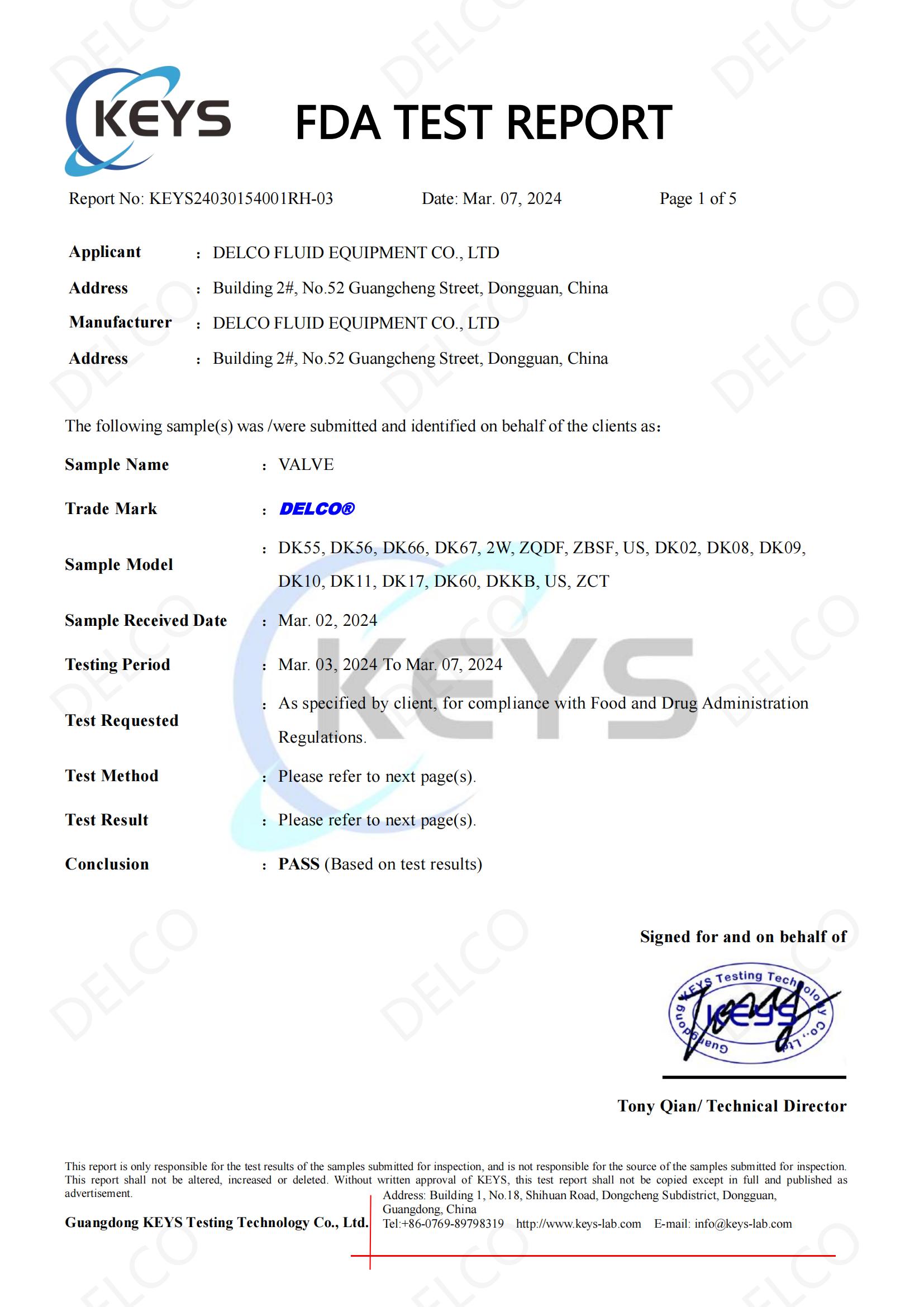

Company Honor

DELCO valve has CE, RoHS, FDA, Explosion-proof electrical apparatus.

For over 20 years, DELCO Valves has been committed to providing our customers with high quality valves.

DELCO has always been centered around one thing: 100% customer satisfaction. We strive for continuous improvement in all aspects of our daily operations. Our mission, coupled with a product line that is manufactured to the highest quality standards, continues to be what sets us apart from our competition. At Powell, all of our facilities are ISO 9001 “Global Quality” certified.

As a leading manufacturer of industrial valves, we offer a wide range of products. Our product lines include: gate valves, check valves, globe valves, check valves, double plate check valves and high performance butterfly valves. With the most complete multi-turn product line from a single-source manufacturer, our valves are manufactured to the highest quality standards using ultra-modern manufacturing techniques and astute material sourcing.

As a full-service valve company, we offer a wide range of products as well as retrofit and field services. Our valve expertise is unrivaled and we look forward to meeting your future valve needs!